Club outing to Lewmar on Sat 16 March

42 of CYC’s best gathered in Lewmar’s reception area at Havant on a slightly wet and very windy day, there was plenty to look at while the last few arrived. Yes there were hatches and winches of every size, but the range of other nautical equipment on show was a surprise. Windlasses, steering gear, hardware, hydraulics, etc laid out in all its shiny splendour. Glass windows and patio doors of all shapes and sizes were marvelled at as we drunk our welcoming cup of coffee before the official welcome by the team from Lewmar.

Alex and Bob welcomed us and gave a potted history of the business. Len Lewery started a company making Tufnol dinghy fittings in 1946 and he was joined by Leslie Marsh, a local plant hire operator in 1950. They called the company Lewmar. Henry Shepherd, whose company made helicopter gearboxes for Westland, bought into Lewmar in 1959 and used his knowledge of lightweight aeronautical materials to develop the multispeed, top-action winch we recognise today. Their pride in the company and its products shone through.

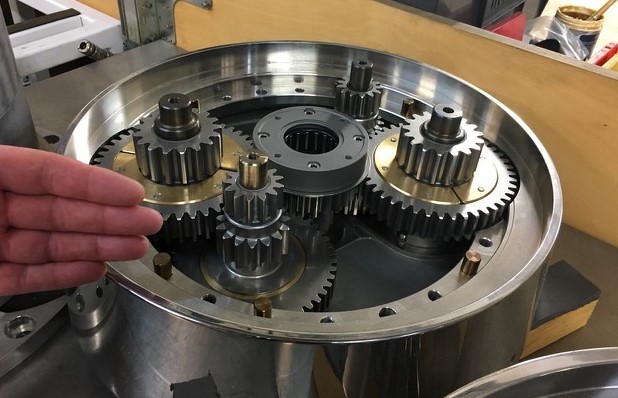

We then had a tour of the production facilities, which are split between the product ranges that Lewmar is better known for and the bespoke glazing production. Split into two groups, we saw just how labour intensive many of the procedures are. From assembling jammers to anchor winches, all involved many parts, and much dexterity from those involved. It also surprised me just how involved in the production Lewmar are, even the cogs for the winches being milled out from bronze blanks. It did strike me just how clean neat and tidy the unit was, very impressive.

More impressive still was the production of bespoke Windows and doors mainly for leisure Motor Yachts such as Sunseeker. Some years ago it became obvious to those at Lewmar that there was a demand for glass. Leisure boaters wanted their vessels to follow the trend of homes and have larger windows. So in 2014 Lewmar invested heavily in the machinery and talent required to launch an entirely new range of glass & glazing products. From flat to curved, monolithic to laminated, fixed to opening and clear to full-colour frit printed. For those that wondered what frit printing meant, frit is a durable, temperature resistant ink that is composed of glass and ceramic particles. The ink is fused into the glass at high temperature after printing.

To see the production, from cad scribing of the glass through the operator with 35 years in the glass industry snapping out an ellipse that was about 2m long, that’s skill. On to the milling machine to profile the edge, then the print room for a detailed examination of the glass for imperfections. If found the glass was scrapped. If deemed perfect the glass was printed with the black edging which was then fused to the surface and the glass toughened. The glass went on to pass through a huge oven before being quenched to toughen it with jets of cool air.

After a farewell and big thanks to all the Lewmar team we retired to Langbrook Farm for lunch. Many thanks go to Kevin & Annie Brown for reorganising the trip, the diversity of product and the enthusiasm of the team made it a very enjoyable and informative trip.

– by John Gosnell